Advancing Metal Finishing with Seamless Automation

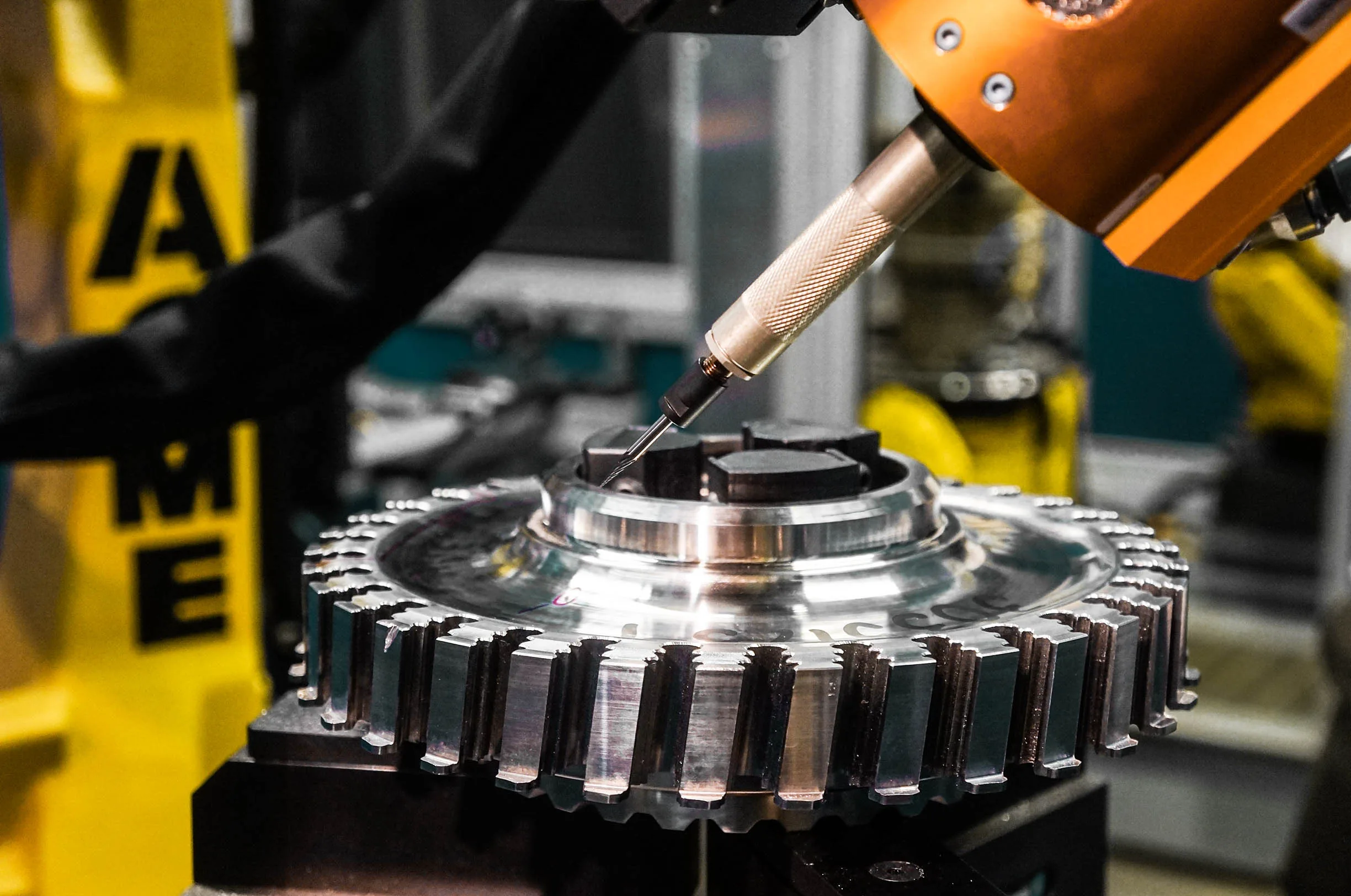

The manufacturing world is shifting towards smarter, faster, and more consistent systems—and at the heart of this transformation lies the AUTOMATIC DEBURRING MACHINE by Valgro India. Designed to deliver flawless surface refinement without manual involvement, this high-tech solution eliminates sharp edges, micro-burrs, and imperfections with remarkable accuracy. By replacing traditional labor-intensive processes, Valgro India is setting a new benchmark for industrial finishing systems.

Eliminating Burrs with Unmatched Accuracy

Burrs are inevitable in metal cutting, drilling, and machining. Left untreated, these small but critical imperfections can lead to compromised product quality and reduced component lifespan. The AUTOMATIC DEBURRING MACHINE from Valgro India addresses these concerns with precision-engineered technology. Whether it’s complex metal forms or flat sheet surfaces, this system guarantees consistent edge refinement with every cycle. With zero reliance on manual finishing, manufacturers can now produce components that exceed quality standards effortlessly.

Enhancing Efficiency Across Applications

From aerospace structures to fabricated sheet metal, Valgro India’s AUTOMATIC DEBURRING MACHINE serves multiple industries seeking speed and reliability. The automation in this system allows it to perform repetitive tasks without fatigue, delivering uniform finishes on large volumes of components. This increase in throughput not only accelerates production timelines but also enhances cost-efficiency for businesses that prioritize scale without sacrificing precision.

Consistency Without Human Error

Manual deburring has long been a source of variation and inconsistency in manufacturing. Different operators may produce slightly different results, impacting product uniformity. With an AUTOMATIC DEBURRING MACHINE, this challenge is eliminated. Valgro’s machines are programmed for repeatable performance, ensuring that each part receives the same attention to detail and refinement. The automated process significantly reduces human error, making it an essential tool for manufacturers demanding perfection.

Intelligent Engineering and Technology Integration

The AUTOMATIC DEBURRING MACHINE by Valgro India is a blend of mechanical innovation and smart control systems. Featuring precision brushes, adjustable pressure settings, and digital interfaces, these machines are built for high adaptability. They can handle various metal thicknesses and surface types without requiring frequent recalibration. This intelligent setup makes Valgro’s machines ideal for dynamic production environments where adaptability and control are key performance factors.

Supporting Safer and Cleaner Work Environments

Safety is a critical consideration in metal processing. Manual deburring often involves exposure to sharp edges, dust, and abrasive materials. The AUTOMATIC DEBURRING MACHINE mitigates these risks by minimizing operator contact and integrating features such as dust extraction and enclosed processing zones. This results in a cleaner, safer working environment, contributing to better employee health and a more sustainable production floor.

Tailored Solutions for Industry-Specific Needs

One of Valgro India’s strengths lies in its ability to customize the AUTOMATIC DEBURRING MACHINE to suit different industry requirements. Whether a client needs compact systems for small-scale precision parts or heavy-duty machinery for high-volume processing, Valgro offers versatile models that can be adapted to specific applications. This customization extends to brush configuration, conveyor systems, and speed controls, giving manufacturers full control over their finishing operations.

Building Global Competitiveness with Smart Deburring

Global industries demand quality, speed, and consistency—all of which are delivered through the AUTOMATIC DEBURRING MACHINE by Valgro India. By removing the dependence on skilled manual labor, businesses can overcome labor shortages, reduce training overhead, and maintain uninterrupted production cycles. Valgro’s systems help companies align with international manufacturing standards, giving them a competitive edge in global markets where precision is non-negotiable.

Conclusion: The Future of Finishing is Automated

Valgro India has redefined what manufacturers can expect from surface finishing with its AUTOMATIC DEBURRING MACHINE. Through intelligent automation, unmatched consistency, and superior safety features, these machines provide a complete solution for edge refinement without manual effort. Industries focused on growth, precision, and quality are turning to Valgro’s automated systems to meet rising demand and tighter production schedules. The era of manual deburring is fading—automation is the future, and Valgro India is leading the way.